Acrotech Inc. has been manufacturing and selling custom roll bending machines equally as long as manufacturing Urethane products. We take pride in our robust well built sheet metal rolling machines and we are proud to say that the majority of them sold are still in use today. Some metal roll bending machines take more abuse than others and this brings us to the question, Should you replace your machine? Scrap it out? Start over? The answer with Acrotech and older Diacro Machines is, send it back for a complete restoration. We are able to upgrade or repair a bender in almost any condition. We will support and service the 1212, 1618, 1824, LD / HD and V-1006. If you have an older model not listed please Contact Us we will be happy to help assist you!

Restoration Features and Options

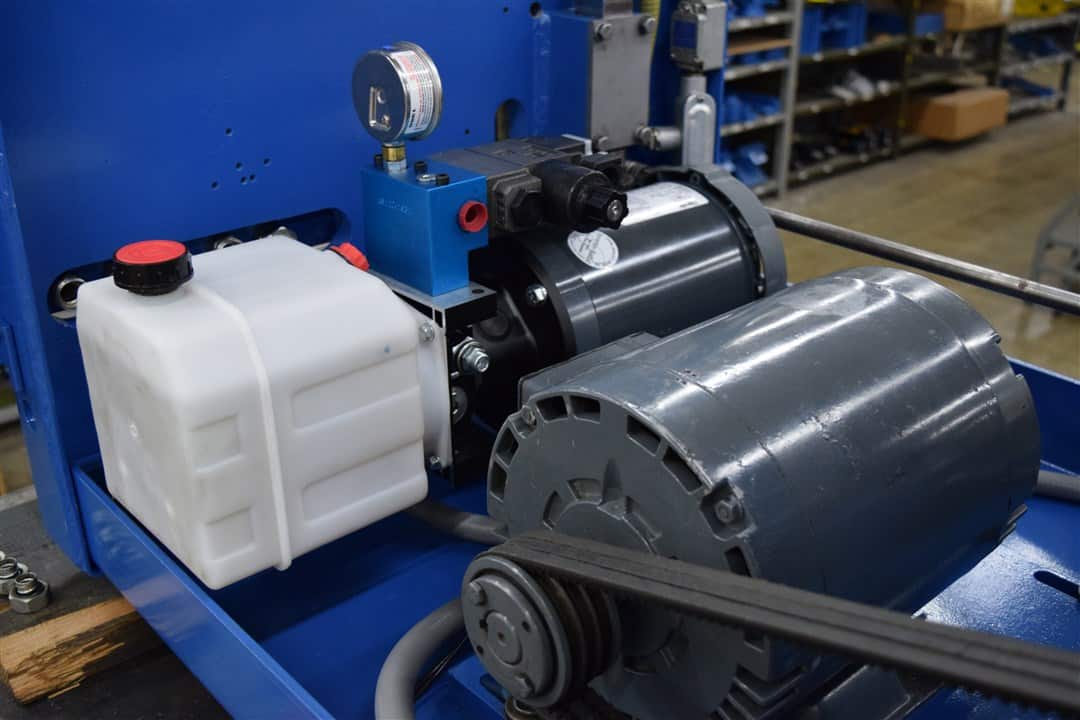

The pictures below show just how used the HD rolling machine was when we got it in. After years of reliable usage the machine was still going strong. The overall costs for each units restoration of course is based on what is needed however you can expect to pay less than half of a new machine in most cases. On some of our smaller machines we may be able to send out parts or recover rollers without the need of shipping the entire machine back and forth.

Our in house staff that builds and restores these machines really take pride in what they do. The results speak for themselves, one might argue that is an entirely different machine. If you have a question about an older Diacro or Acrotech Roll bending machine please Contact Us.